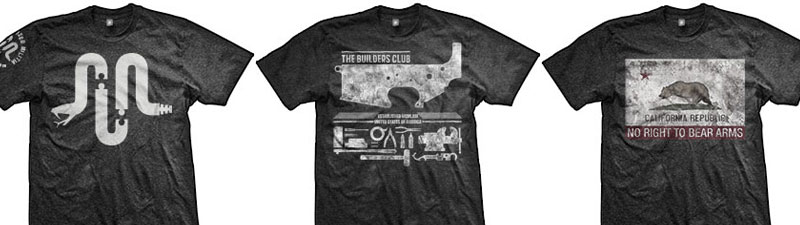

They have another few printers that print money:

Full writeup and more pics over at DefDist.

My suspicions were correct when I criticized the function test of this printed AR-15 lower:

The new AR lower was SLA and FDM printed. The FDM printer was a used Dimension SST, and the material was p400 ABS.

A quick look at the Dimension SST page and….. Cost: $32,900 *facepalm* I’m sure theirs was like $1000 max on the used market though right? haha

They go on to say this at the end – “the big takeaway is that you can do what we did on a printer like the Ultimaker or RepRap. The pieces can be made cheaply” haha yea… OH it will print. Do that and tell me how many rounds you get out of it.

Like I said numerous times… people can keep shitting bricks over this, but I’ll only be impressed when thousands of youtube videos pop up from people with RepRaps and Makerbots who are pumping out their own mags and lowers. I know it will happen, and I wish this project would lean more in that direction.

Thoughts?

Comments

22 responses to “Defense Distributed Is Richer Than You”

supposed to be 600 rds + before failure now..

http://youtu.be/tAW72Y_XPF4

That’s the same video I posted and linked to.

yea.. just saying.

home print ability- (for ALL THE $$s)

is still home print.

i totally get what you’re saying.

but it’s still a step in the right direction.

even if you and i didn’t invest in mac or apple in the late 80’s.

as a side note..

what’s a CNC Machine run these days?..

Industrial CNC machines I’ve seen go as low as $12k

You can get a used knee mill with a CNC controller $8k easy.

While I am in no hurry to try to print anything or drop huge sums on the printer itself…it is always cool to see stuff like this.

i say mike should buy a printer, make some endo lowers, sell 100 for $500 each to the suckers that are running around right now and profit.

“Guaranteed 300 Rounds”

The guy is still a ban crazy lib. He doesn’t want to ban the guns….he wants to ban the gun powder.

http://www.theblaze.com/stories/2013/02/19/engineer-dont-regulate-3d-printed-guns-regulate-explosive-gun-powder-instead/

I’m pretty sure that’s a different person.

Yeah, that turd is named Hod Lipson. Cody Wilson is the guy behind DefDist and he’s a law student at UofT, not an engineer.

I had seen plans out there before that was for a receiver that was much easier to print that bolted together. I wonder if that kind of receiver design would be much better for the DIY with a cheaper 3D printer to do this. Found it: http://www.scribd.com/doc/97323902/60995712-Scratch-Built-AR-15-Bolt-Together-Receiver-Plans

You could make a working lower with about $5k in surplus machining equipment and some rudimentary skills. Or you could get injection mold dies made for $5 to 10k and make polymer lowers. I haven’t looked at the cost of a surplus injection mold setup of that size recently, but it would be a bit more expensive. This “OMG 3D PRINT EVERYTHING” fad is retarded. It is a good process for one-offs but not so hot for mass production or manufacturing parts with a similar level of durability as injection molded polymer. People have been making stuff out of metal using actual machine tools for a few centuries now. The way people sound when they rant about being able to 3d print stuff makes it seem like all of the objects we use in our daily lives and take for granted were materialized out of thin air by the flying spaghetti monster with no human input whatsoever. As it turns out, we have these people called engineers and machinists who use skills to design and manufacture things.

Wait…so you’re telling me that people can make things? I thought AR-15s were given to use by the gods and their was no way a person could ever develop one on thier own!?!?!

heh. there are a few threads on weapons guild now where guys are making ar15 receivers with nothing more advanced than a welder. even uppers.

I dont understand what the big draw of 3D printing lowers in plastic is. CNC has been around since the 60’s.. You can find used MAX CNC and similar setups on ebay for a few grand. CNC retrofit kits are available for pretty much everything from the cheap harbor freight mills to smithys and 50 year old bridgeports. Commercial conversions that can run a few grand to dirt cheap DIY setups.

Certiantly cheaper than commercial 3D printers and 1000x better tollerances than any neckbeard reprap.

It;s this sort of shit that makes me realise how much our shitty society panders to the fucking moronic lowest common denominator. You can make a STEN gun in 43 basic machining steps, the fucking government told people how to do it in their sheds during WW2.

If you’re wanting to stay legal though, an AR lower would be easier. If you’re making a STEN, you’d have to not only convert it to semi-auto but also convert it to fire from a closed bolt. Plus, 16″ barrels on STENs look silly.

Omg. The implications. Glock 7’s that bypass airport security measures ( a la Diehard ) in the not so distant future.

Sure beats the Surefire Pen. LOL

Looks like it’ll glow in the dark.