Tag: stratasys

-

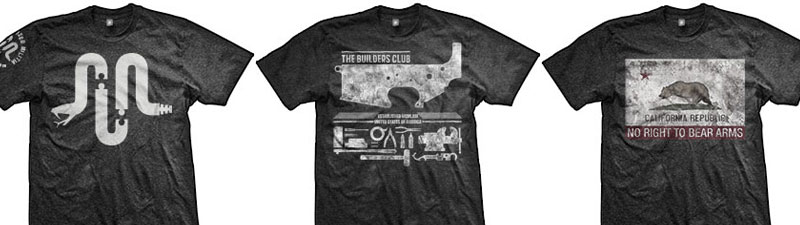

Defense Distributed AR-15 Lower

These guys market this like they are doing the Lord’s work: Watching that guy pull the trigger was painful. Slappy Mc2ndKnuckleSlapperson. Maybe I’ll eat my words when someone says they printed that out on a $200 RepRap, but my guess is they have some sort of fancy printer similar to the $20,000 one Stratasys yanked their…